Regd. Office : 710, Embassy

Centre, Nariman Point, Mumbai - 400 021.

Tel. : 022 - 4333 4000 /

Email Id :

marketing@shreetecs.com

Broken Bag Detectors are also called Solids Flow Monitor - FM-10).

A) DETECTION OF A BROKEN BAG in Fluid Bed Drier (FBD) / Processor (FBP) / Rotary Vacuum Dryer (RVD), resulting in saving of product losses.

B) DETECTION OF A BROKEN BAG in Filter Bag House, resulting in efficient pollution and emission monitoring / saving of product losses / prevention of contamination of production line / preventing damage to downstream equipment.

When the drug / product is being dried in the FBD / RVD, product losses often occur due to ruptured filter bags. Significant product losses can occur by the time the filter bag rupture is detected & the FBD / RVD is stopped. The Broken Bag Detector is used along with the FBD / RVD for preventing product losses due to ruptured filter bags (or broken sieves) by immediately sensing the leakage and stopping the motor of the FBD / RVD.

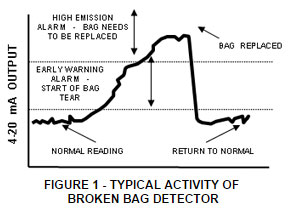

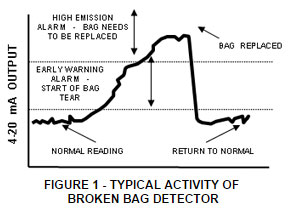

It has been observed that the filter bags are replaced every 2-3 months to avoid leakages. BBD can serve as an early warning system indicating possible failure of bag in the near future by detecting higher emission levels enabling the bag to be replaced in time. This is possible by using an analog output (optional feature) which would be proportional to the mass flow of solids / particulates. This analog signal can be connected to an indicator or recorder in the control room or to the PLC of the FBD (as shown in Figure 1 & 2).

Maintenance costs are reduced since the downstream equipment such as blowers, fans etc., are protected from spilling powder. Labour required for cleaning operations after bag ruptures is also saved. Above all, bag ruptures may lead to batch losses, forward sections of the plant remaining idle, production targets not being met, penalty clauses / order cancellation and lowering of corporate image which could be avoided by installing the Broken Bag Detector.

The Broken Bag Detector is highly sensitive and reliable. It consists of a Sensor with shielded cable and an Electronic Control Unit. The Sensor is a 316 stainless steel rod with Teflon Insulator. The Sensor is installed in the duct of the FBD as shown in Figure 3.

When the leakage of the product takes place through the ruptured filter bags (or broken sieves), the product strikes the Sensor. This results in the generation of an analog electric signal directly proportional to the mass flow of the colliding solid particles. This signal is then conditioned, amplified & processed through sophisticated electronic circuitry and then used to give an alarm and finally to stop the motor of the FBD / RVD thereby preventing product losses.

The Broken Bag Detector is not only used in the Pharma industry, but is also used wherever an FBD with Filter Bags is used – Chemical, Fertilizer & other such industries. The FM-10 is also used for other applications like monitoring the flow of materials from hoppers / silos / bins / any type of vessel to the downstream equipment & giving an alarm in the event of failure / stoppage of the flows.

The Broken Bag Detector is the most efficient and economical instrument for: